Engineered Acoustic Enclosures for Chillers

Ever had a project stall because of unexpected noise complaints? Chillers may be the culprit.

Noise is frequently overlooked in the design of mechanical equipment, only becoming a problem once the equipment is installed and the neighbors start complaining. If the local authorities find that a site has violated noise ordinances, the situation needs to be remedied quickly to avoid legal action.

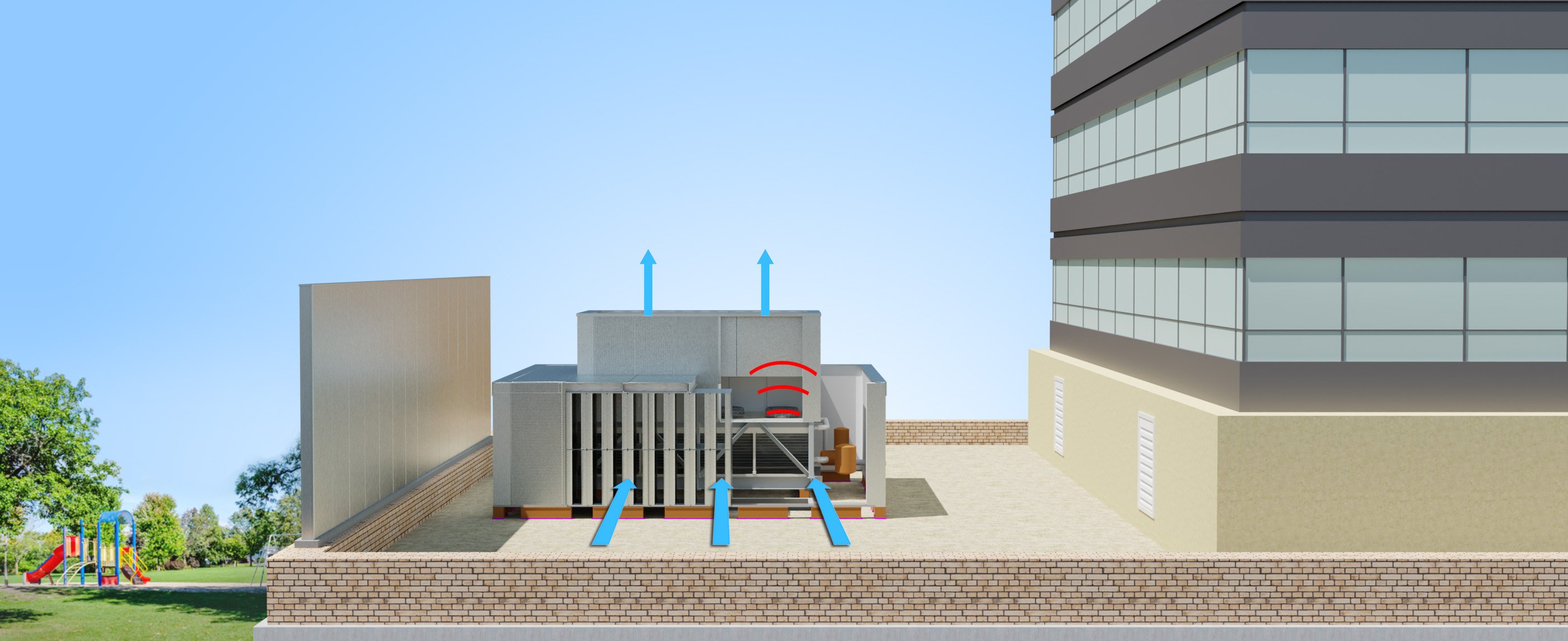

It is common for noisy equipment to be installed near occupied spaces, such as outside of schools, offices and housing. Typically, we treat the noise at the source with a site-specific solution. There are multiple products to choose from to solve this problem, with two popular solutions involving the use of a barrier wall, which blocks the sound from propagating, or an acoustic enclosure, which contains and reduces the sound.

|

| A chiller with a Price Acoustic Panel enclosure and an adjacent barrier wall |

Both these solutions can be made from Price Acoustic Panels. Acoustic enclosures are especially effective when sound-sensitive spaces are located above the equipment or when a sound-level reduction greater than 15 dB is required. The Price Noise Control team can also perform an acoustic analysis on the project to determine the mix of products needed to reach the required sound levels at the property line.

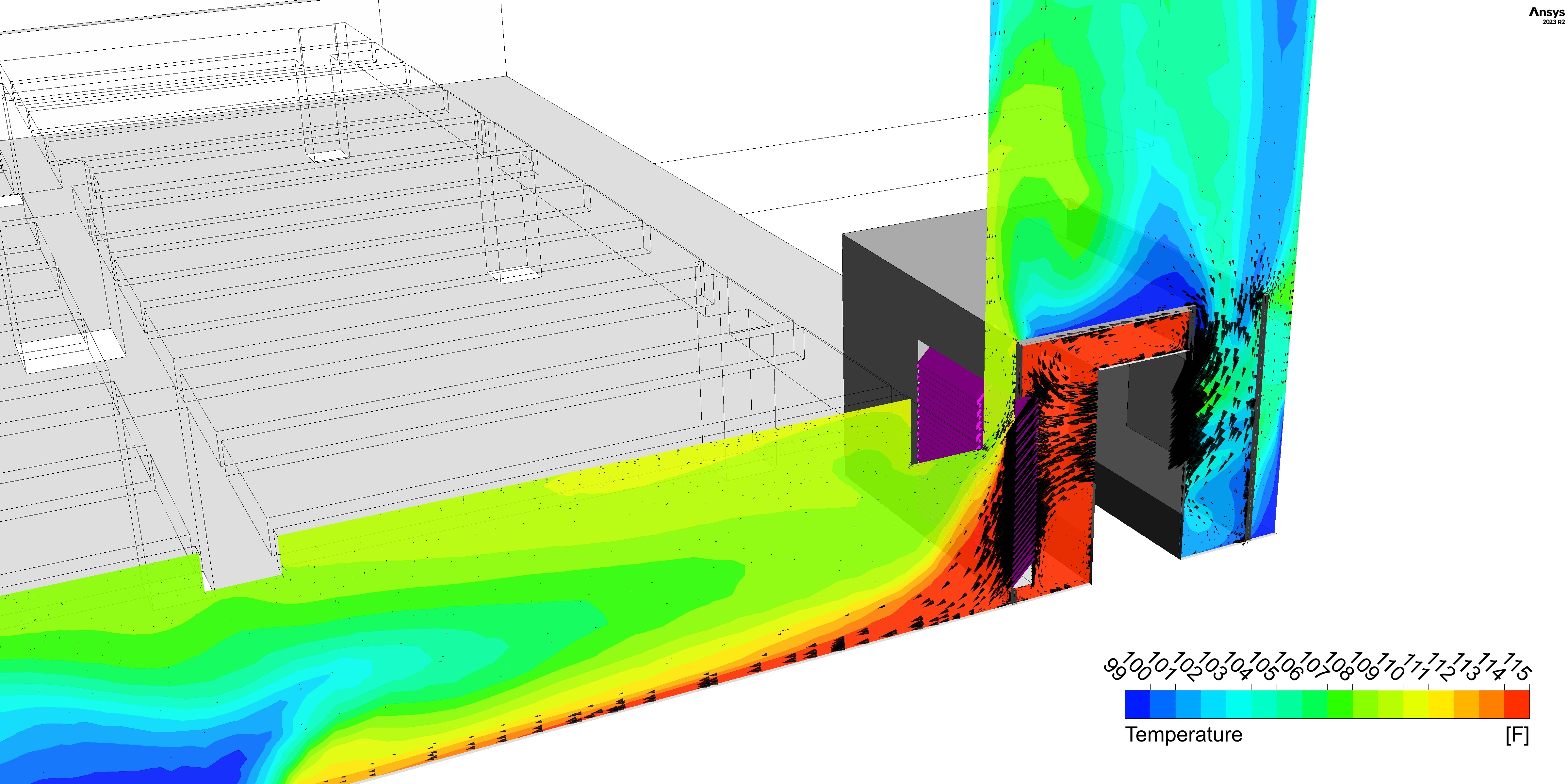

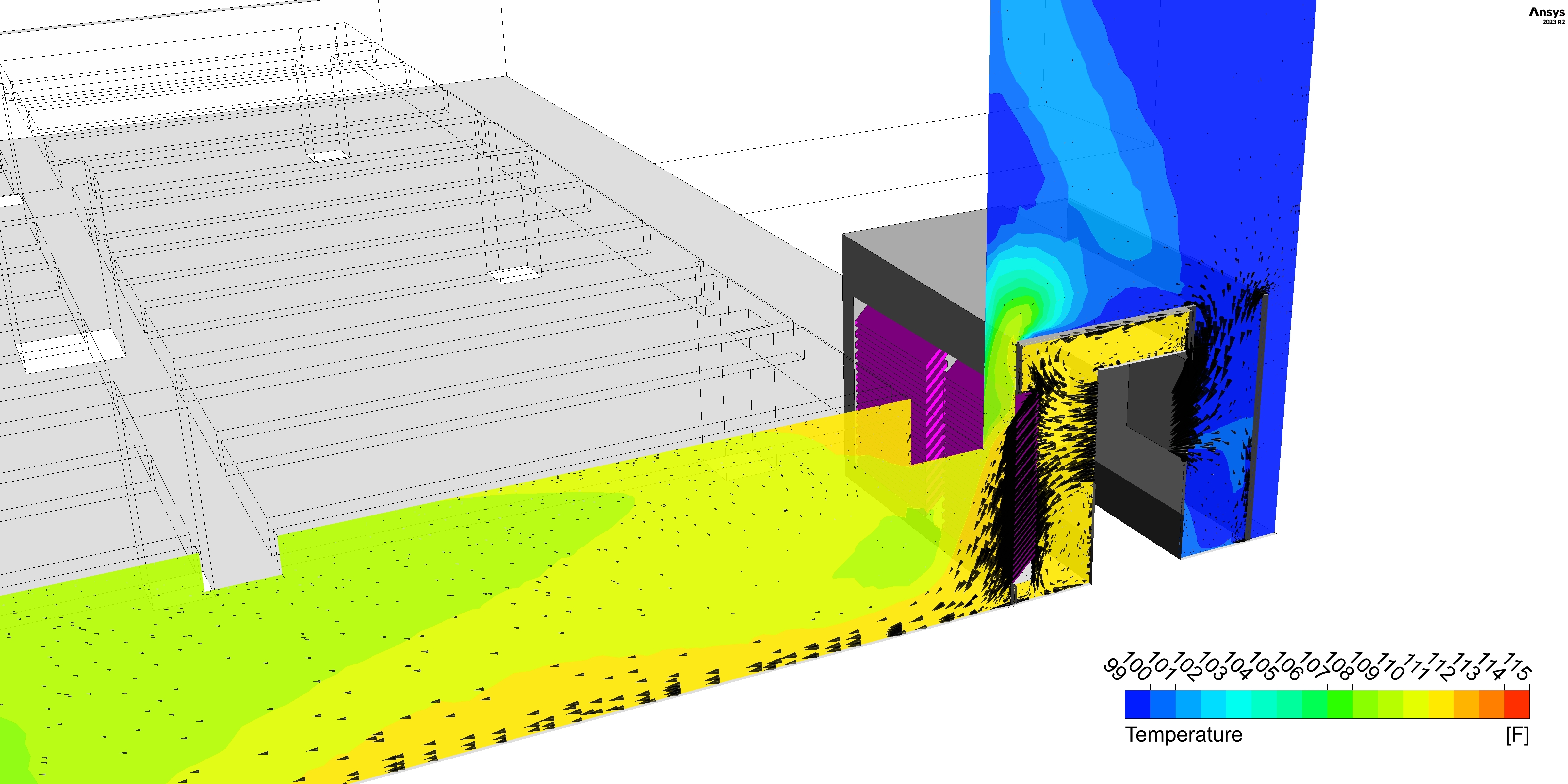

An important design consideration for acoustic enclosures is the pressure drop they – and their structural components – impose on equipment such as chillers. This added pressure drop can degrade equipment performance and, in some cases, may even void the manufacturer’s warranty. Having the Price Predict team conduct a computational fluid dynamics (CFD) analysis of the enclosure is a great way to ensure that any impact on the chiller’s thermal performance is minimized. The results from the CFD analysis are used to quantify the effect of the enclosure on the chiller’s capacity and airflow, and the experienced Predict team can then help fine-tune the enclosure design to minimize these effects.

|

|

| Temperature plots of the acoustic enclosure with overlaid airflow direction; compare the original design (left) to the fine-tuned design (right) that shows a reduction in recirculation and inlet temperature | |

On a recent project, a chiller was generating too much noise and required an acoustic enclosure to meet the noise ordinance at the sidewalk (the property line) and an adjacent patient room. A CFD analysis was performed to optimize the airflow to the chiller, minimize recirculation and achieve a low pressure drop of 0.06 in.w.g. The final design met the acoustic criteria for the project while maintaining nearly all of the chiller’s cooling capacity.

|

| A Price Acoustic Panel chiller enclosure with intake and discharge silencer banks |

The acoustic performance of the enclosure could be improved further with thicker acoustic panels (4 inches, 6 inches or a custom thickness) and/or Price’s Rectangular Silencers (model RH, which features geometry for ultra-low pressure drop) on the intake and discharge of the enclosure.

|

| Side-by-side chillers with Price acoustic enclosures showing the intake silencer banks |

Contacting the Price team early in the design phase of a project allows us to provide engineered solutions that avoid undesirable noise levels before the complaints start. By packaging Price Noise Control products with Predict’s CFD expertise, we deliver a holistic solution – including acoustics, airflow dynamics and professional-engineer-stamped structural services – that meets local noise bylaws and minimizes impact on equipment capacity.

Let’s design for silence from the start. Visit our website or contact our team at noisecontrol@priceindustries.com to ensure your next project stays quiet – and compliant.

|

Steven Thomasson is Business Development Lead for Price's Noise Control team. He is based out of Price's headquarters in Winnipeg, MB. Click here to connect with him on LinkedIn. |

|

Mike Koupriyanov is Manager of the Price Predict team. He is based out of Price's headquarters in Winnipeg, MB. Click here to connect with him on LinkedIn. |