Measures to Mitigate Condensation Concerns

More than ever before, engineers, contractors and building owners are choosing chilled beams for their projects. This energy-efficient technology uses the heat transfer capabilities of air and water to provide heating and cooling in a space. But the concept of installing a water coil within the housing of the chilled beam raises some very important questions: will there be condensation, and are drain pans required?

The answers to those questions depend on the application and the temperature of the chilled water entering the system.

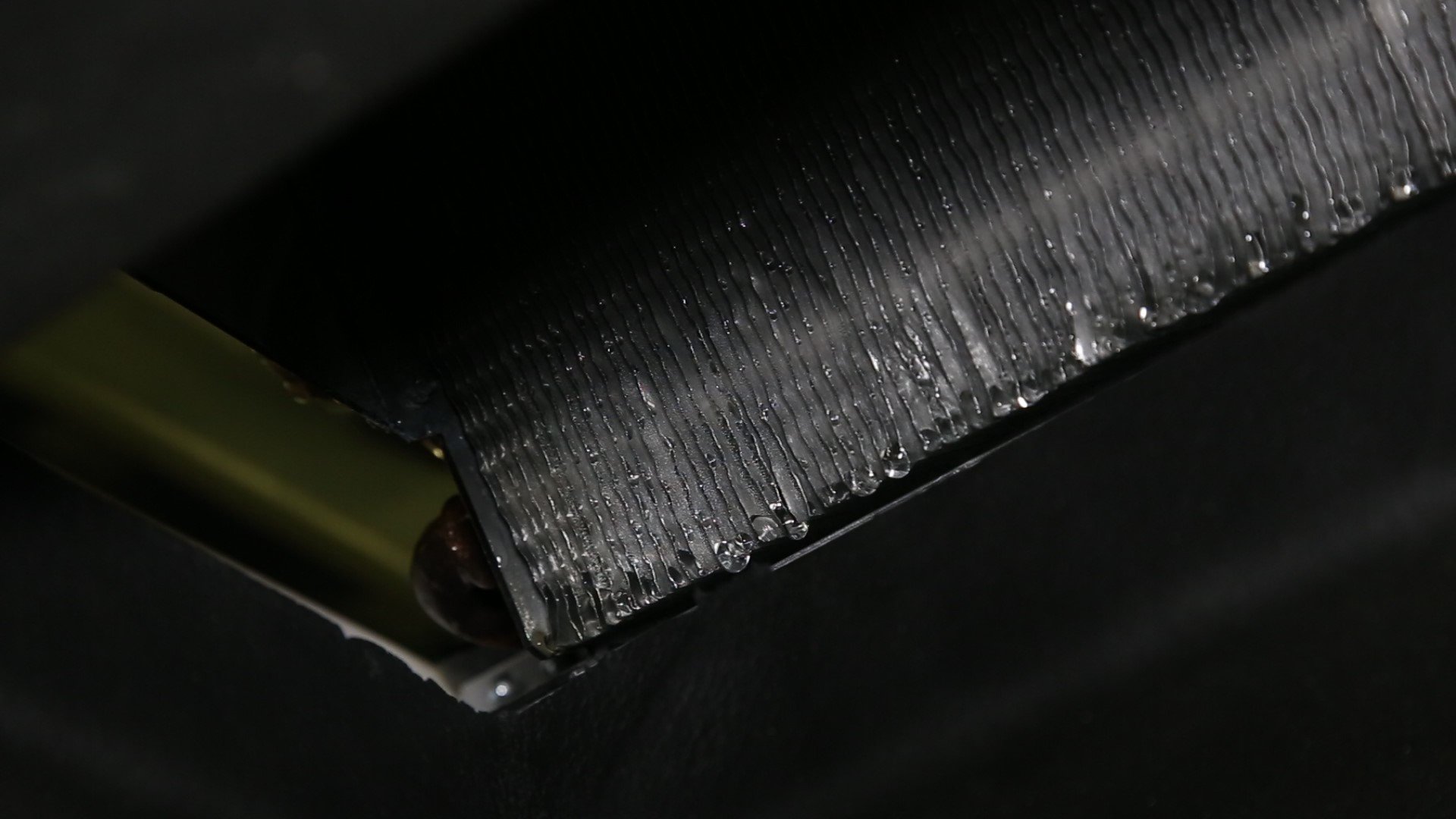

|

| Condensation forming on water coil fins |

The Application

Condensation on the surface of a water coil accumulates if the water temperature is below the dew point temperature of the surrounding environment. For applications where the space dew point is left unchecked or where there is an uncontrolled influx of moisture due to a weak envelope or an open window or door, measures should be taken to mitigate condensation concerns. These measures include using a chilled beam model equipped with a drain pan, control schemes involving condensation or dew point sensors to monitor and react to changes in the ambient conditions, or a combination of the two.

Water Temperature

Condensation is also influenced by the temperature of the water being supplied to the chilled beams. This temperature can be split into two categories: low temp and tempered. Low temp chilled water is associated with the primary chilled water loop that runs through a building. Tempered chilled water is water that is treated, typically in a secondary loop in the building, so the temperature is above the space dew point.

Chilled beam systems utilize water with a temperature that is 2°F–3°F higher than that of the dew point. These systems will not require drain pans with proper controls in place in addition to a sealed envelope. It is also important to consider that condensation takes time to accumulate and become heavy enough to fall, so it can be prevented with control schemes that shut off the chilled water if space dew points rise above a desired level or if condensation is detected ahead of time.

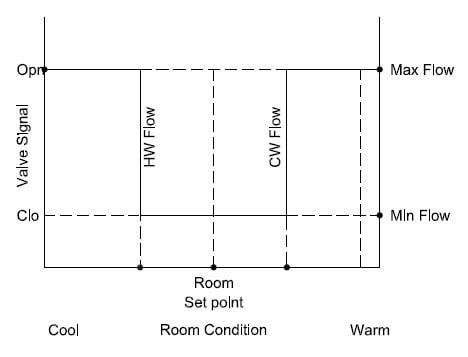

Here is an example of a simple control sequence:

- Cooling: With an increase in room temperature above the room set point, the hydronic valve opens to allow cold water to flow through the chilled beam system. If the system water is hot, the valve remains closed. With a decrease in room temperature out of the cooling proportional band, the hydronic valve closes.

- Heating: With a decrease in room temperature below the room set point, the hydronic valve opens to allow hot water to flow through the chilled beam system. If the system water is cold, the valve remains closed. With an increase in room temperature out of the heating proportional band, the hydronic valve closes.

- Deadband: When the room is satisfied, the valve is in the closed position, preventing any water flow to the beam.

- Condensate sensor: When the switch is closed (upon detection of condensation), the controller closes the hydronic valve to stop the flow of water to the beam. The status of the sensor is reported over BACnet.

|

| Binary two-pipe control graph |

There are benefits to using either tempered or low temp water. Tempered water applications will remove the necessity for drain pans and drain lines and the labor associated with installing and maintaining those drain pans and lines. However, low temp applications allow for more cooling capacity and can remove the need for a secondary chilled water loop. Weighing these benefits from a cost, labor and maintenance standpoint means that the chilled beam system can be designed accordingly.

For more information about chilled beams and the best design for your particular application, visit our website or contact us at beamteam@priceindustries.com.