The Induction Process and the Science Behind Chilled Beams

Although perceived as an up-and-coming technology, chilled beams have been around for years. This system offers many benefits, including energy savings over the lifespan of a project, reduced duct sizing, lower noise levels and minimal required maintenance.

The goal of the chilled beams technology is to move the energy required to maintain a comfortable space condition from the air side (air handler) to the water side (chiller or boiler). But how does the chilled beam provide cooling through its water system? The answer lies within the nozzles of the chilled beam and the induction process that these nozzles create.

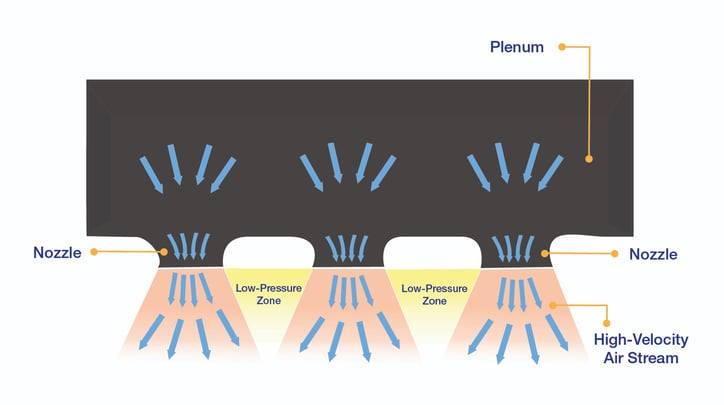

A chilled beam is a sensible load treating device that takes in primary air from an air handler. The air is sent to the chilled beam’s integrated air plenum, where it gets pressurized and is released through a series of nozzles. These nozzles are engineered into a specific hole pattern through which a stream of air will discharge at a high velocity.

This high-velocity airstream then creates a low-pressure zone, promoting induction through the water coil – a process sometimes referred to as entrainment. This induction effect pulls in additional air due to a pressure differential created by the discharging airstream velocities. The mixing chamber behind the chilled beam water coil, specifically near the nozzles, becomes a space of low pressure.

| A detailed look at the low-pressure zone created by the high-velocity airstream |

Air will always travel in the path of least resistance in these pressure differential circumstances. We observe this whenever there is a windy day outside, and induction works in much the same way. As a pressure differential is created in the mixing chamber, air will naturally move into it.

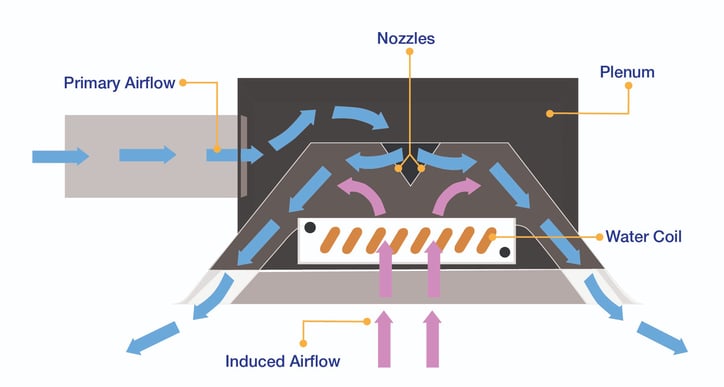

In the specific case of chilled beams, a heat exchanger coil with either chilled or hot water treats this air as it is induced from the room side. Through this induction process, the chilled beam will transfer energy from the air to the water coil.

|

The induction process through the water coil |

By researching and developing different geometries, quantities and free areas of these nozzles, we can understand how to vary the rate of induction as well. This induction rate can be increased or decreased to change the amount of airflow moving through the water coil. This is done by selecting the appropriate nozzle for the desired induction ratio, which is the ratio of the amount of air supplied to the chilled beam versus the amount of air induced through the water coil.

Through additional parameters such as air and water temperatures and air and water flow rates, we can fine-tune selections that will best fit an HVAC application. And as an added benefit, this process works for every active chilled beam product, whether you have an overhead, floor-mounted or underfloor chilled beam system.

To learn more about chilled beams, email us at beamteam@priceindustries.com.