Combining the Benefits of Chilled Beams and Displacement Ventilation

Chilled beam systems use the heat transfer capabilities of water to provide sensible cooling to a space. As we’ve discussed previously on the blog, when the system is in cooling mode, the induction process facilitated by the chilled beam nozzles causes warmer room air to mix with the colder primary air, providing the space with supply air with temperatures at 62°F to 66°F – much warmer than the 55°F supply air provided by conventional cooling systems.

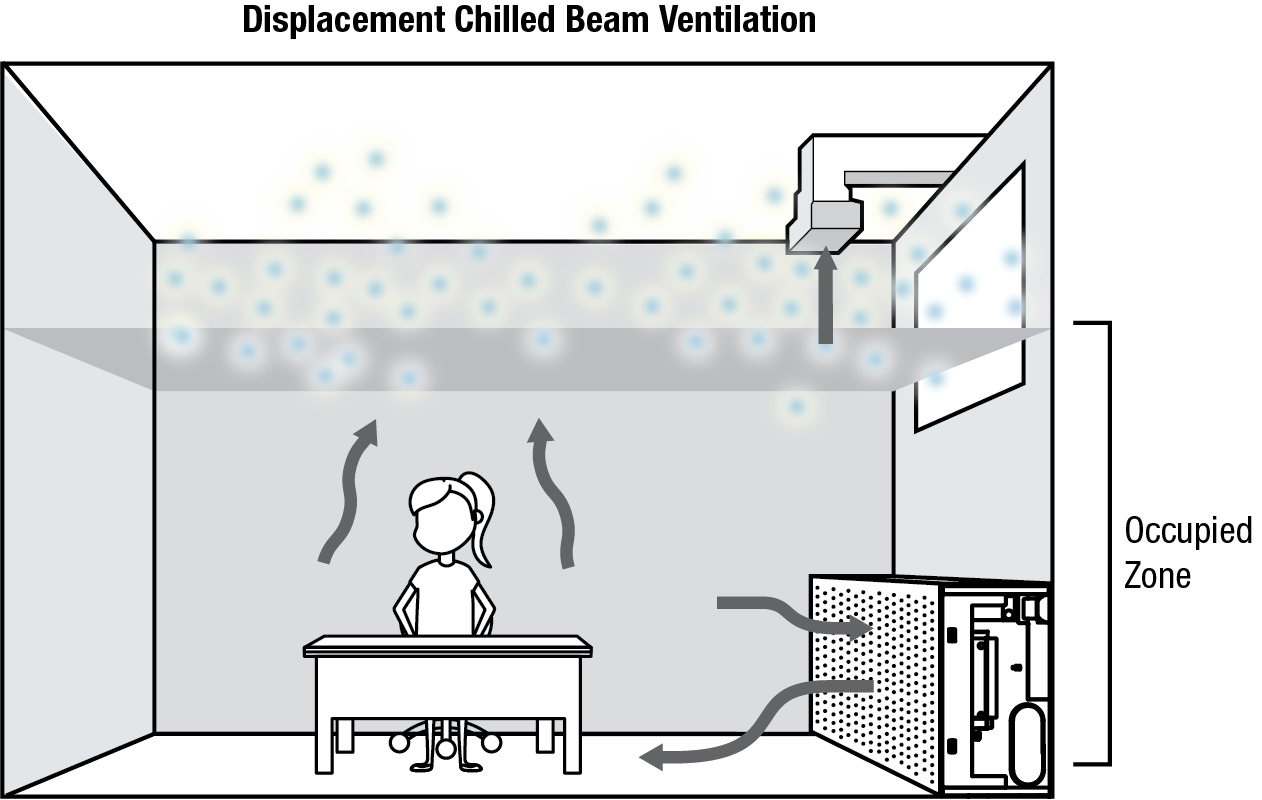

Displacement ventilation systems provide cooling directly to the occupied space at a temperature similar to that provided by chilled beams. With displacement systems, the air provided stratifies and pushes (or displaces) the warm, stagnant air – along with any particulate – out of the breathing zone. The resulting low-velocity air and warmer cooling temperatures together create a comfortable indoor environment for occupants.

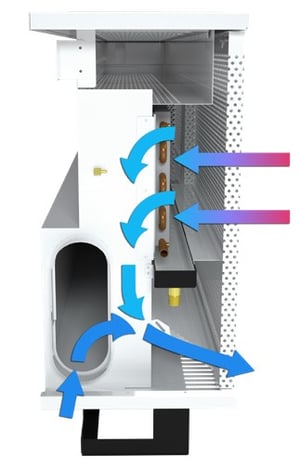

|

| An active chilled beam cabinet installed along the wall of a classroom |

These two methods of cooling can be effectively combined in one technology: Price’s floor-mounted Active Chilled Beam Cabinet (ACBC). This exposed perimeter unit is an energy-efficient solution for high-occupancy applications such as office spaces, lobbies and classrooms.

|

|

| The displacement cooling process (left) as provided by Price’s ACBC (right) | |

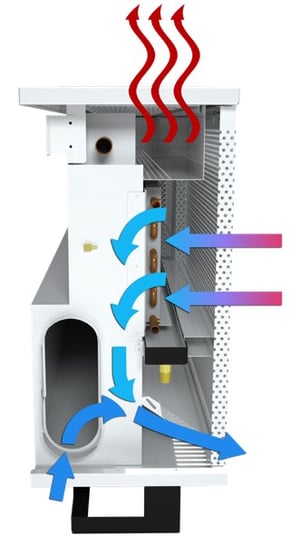

The ACBC is available in several configurations, but only configurations with one-way discharge through the face in cooling mode can truly be considered displacement systems. The reason for this is that with displacement ventilation, having forced air blowing up while in heating mode is not an effective use of the system; this is more characteristic of a typical mixing system. If the warm air stratifies prematurely, it will spread uniformly throughout the occupied zone, and the system’s capacity will not be fully realized.

|

|

|

| One-way airflow cooling (left) and heating (right) configurations of the ACBC | |

The ACBC realizes the benefits of both chilled beam and displacement ventilation technologies:

- Warmer supply air temperatures compared to those of conventional systems, which allow for the utilization of free cooling hours

- Less airflow and ductwork required compared to traditional all-air mixing systems

- Supply air that conditions the breathing level and occupied zone directly

- Minimum in-space maintenance, with no filters, drain pans, wet coils, envelope wall openings or refrigerant lines

For more information about the ACBC and how it can work in your next project, contact the Sustainable Systems team at beamteam@priceindustries.com.