Understanding the Fundamentals

High-efficiency particle air filters, or HEPA filters, are used for air filtration where room particulate control is of the utmost importance, including in cleanrooms, laboratories, pharmaceutical compounding facilities, protective environment isolation rooms and airborne infectious isolation rooms.

Unfiltered room air contains various types and sizes of particles. Predictably, the smaller the particle, the more difficult it is to filter out of the air. HEPA filters are ideal for filtering very small particles, which are measured in micrometers or microns as represented by the symbol µm. To put particle size into perspective, the diameter of a human hair ranges from 17 to 181 microns, most allergy-causing pollen ranges from 10 to 40 microns and duct particles can be as small as 2.5 to 10 microns.

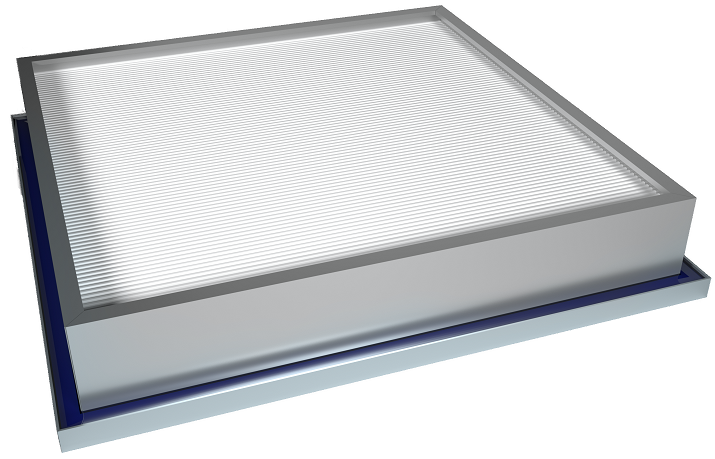

HEPA Filter Media

HEPA filter media is a fibrous media that is typically made of borosilicate glass microfiber elements. Filter media is manufactured so that it creates a tight labyrinth or maze of fibers while maintaining a massive amount of free area. As air passes between and around the tightly wound fibers, the velocity of the air decreases until the particles are ensnared by the glass fibers.

Mechanisms of HEPA Filtration

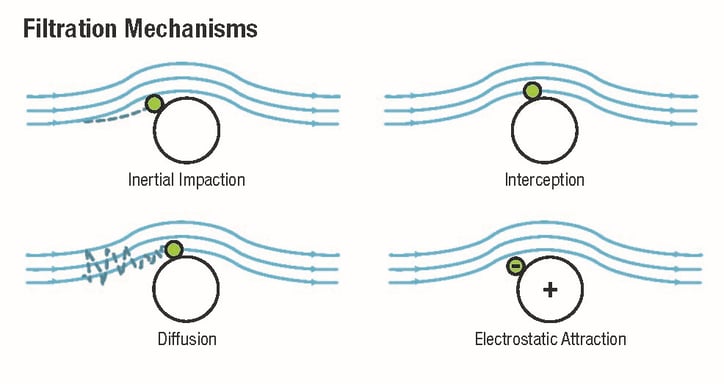

The basic filtration mechanisms are discussed in detail in our previous blog post, Basics of Air Filtration. The image below summarizes the four main filtration mechanisms used in HEPA filters.

- Inertial impaction predominantly occurs on larger particles. Large particles have high inertia, and as the air flows around the fibers, the particles continue along their trajectory and crash into the fibers instead of following the airstream.

- Interception occurs when the airstream carries particles within one radius of the fiber, causing a collision between the particle and the fiber and trapping the particle in place.

- Diffusion affects very small particles (0.1 µm and under). Small particles continually bump into each other as they travel through the air, causing a very chaotic or random zigzagging path. This motion is referred to as Brownian motion. Brownian motion causes particles to collide with fibers and become trapped.

- Electrostatic attraction occurs when particles are attracted to the fibers by electrostatic adhesion. In HEPA filters, this mechanism contributes the least to the efficiency of the filter.

Particle Size and Efficiency

HEPA filters have an efficiency rating of 99.97% at 0.3 µm, and a common misconception is that they do not remove particles smaller than 0.3 µm. This is untrue because HEPA filters do not act like a sieve where particles above a certain size are prohibited from flowing through while smaller particles are allowed to pass; rather, HEPA filters use four different mechanisms of filtration to effectively trap particles of varying sizes.

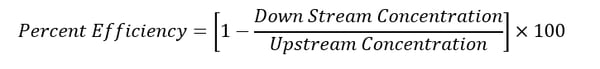

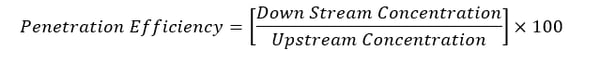

Filtration efficiency percentage is a function of the ratio of upstream particle concentration compared to the downstream concentration that has passed through the filter and is defined by the equation below.

Filter performance is sometimes displayed as penetration percentage instead of percent efficiency. Like efficiency, penetration is also a function of upstream particle concentration compared to downstream concentration that has passed through the filter and is defined by the equation below.

Filter performance is sometimes displayed as penetration percentage instead of percent efficiency. Like efficiency, penetration is also a function of upstream particle concentration compared to downstream concentration that has passed through the filter and is defined by the equation below.

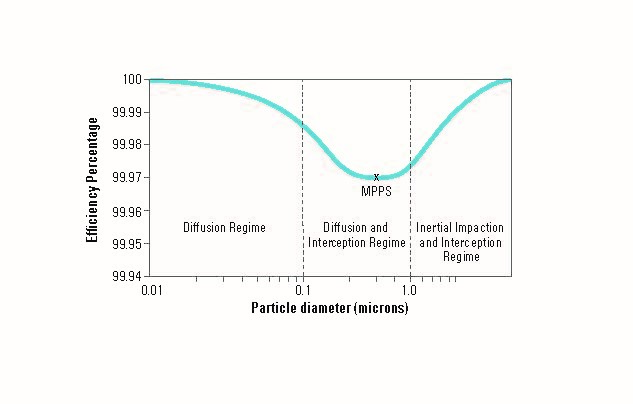

Percent efficiency is the minimum filtration efficiency. Large particles are removed by interception and inertial impaction while smaller particles are removed via diffusion, resulting in the lowest filter efficiency in the median-size particle range. Comparing filter efficiency percentage in relation to particle size, it is easy to see why the median-sized particles become the most penetrating particle size (MPPS). Since most of the filtration mechanisms rely on airflow to be effective, airflow rate will affect filter performance. Higher airflows cause an increase in larger particles to be filtered by inertial impaction and interception. At lower airflows, smaller particles have higher Brownian motion, increasing the number of particles that will be captured by diffusion. As a result, change in airflow rate shifts the filter efficiency curve and alters the MPPS. For expected filtration results and efficiency, it is important to always follow the manufacturer's recommendations for airflow. Certification standards and factory testing ensure that the filtration efficiency listed on the filter label or in the test report is the minimum efficiency throughout the recommended airflow range for the filter.

Since most of the filtration mechanisms rely on airflow to be effective, airflow rate will affect filter performance. Higher airflows cause an increase in larger particles to be filtered by inertial impaction and interception. At lower airflows, smaller particles have higher Brownian motion, increasing the number of particles that will be captured by diffusion. As a result, change in airflow rate shifts the filter efficiency curve and alters the MPPS. For expected filtration results and efficiency, it is important to always follow the manufacturer's recommendations for airflow. Certification standards and factory testing ensure that the filtration efficiency listed on the filter label or in the test report is the minimum efficiency throughout the recommended airflow range for the filter.

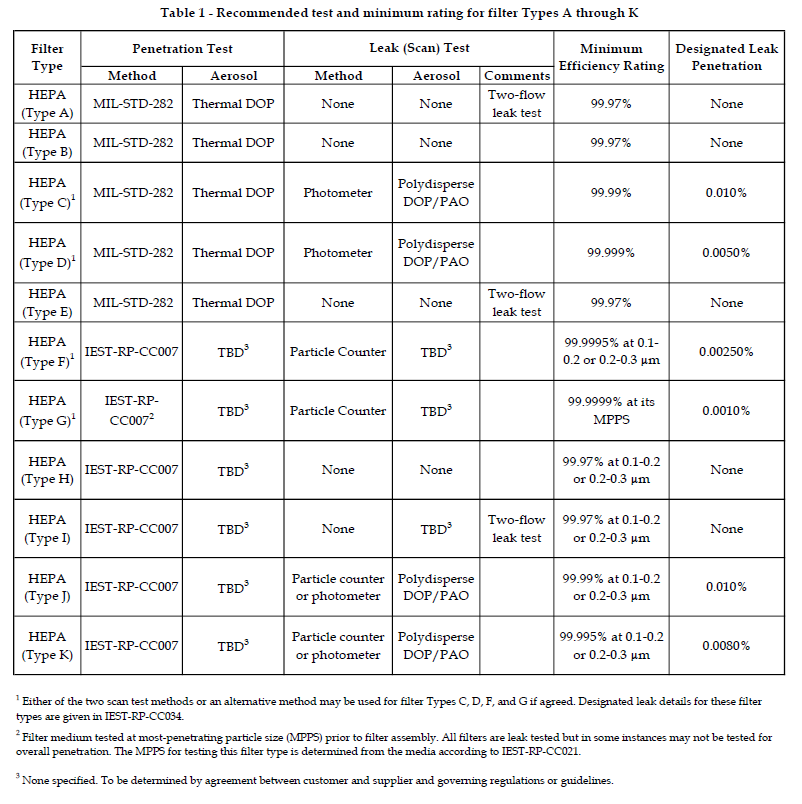

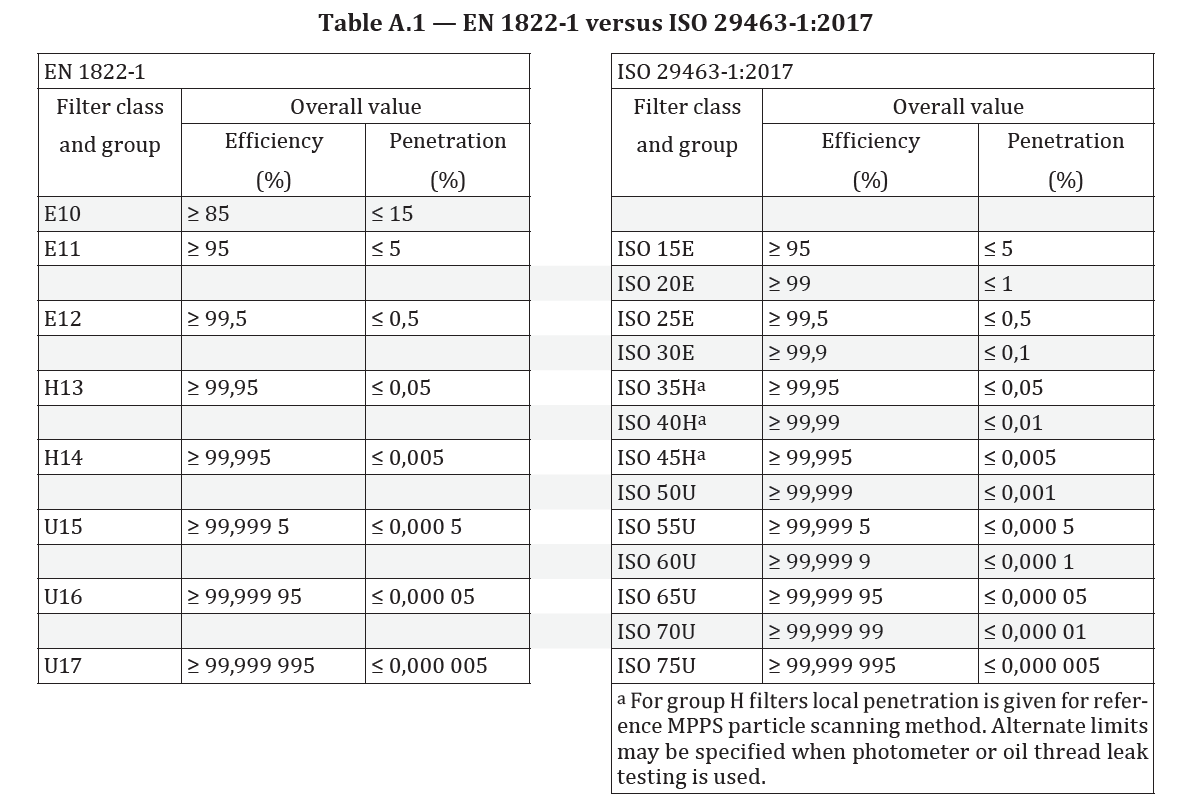

Certification Standards

In North America, the guidelines and recommended practices put forth by the Institute of Environmental Sciences and Technology (IEST) – IEST-RP-CC001, -CC002, -CC007, -CC021 and -CC034 – are the most widely used. In Europe, the standards set up by the European Union, specifically EN 1822, are followed. EN 1822 references ISO 29463, a standard that the International Organization for Standardization (ISO) is working on. Ideally, in the future ISO 29463 will be used worldwide, but it has yet to be adopted in North America and needs to be used in conjunction with EN 1822 in Europe. Below are two tables, one from IEST-RP-CC001 and the other from EN 1822-1, that go over the filter types or filter class and groups and compare them to their corresponding minimum efficiency percentage and leak penetration.

Factory Testing

All filters that have been manufactured and tested in accordance with either IEST or EN 1822 will have a label and a test report available that state the filter's performance. The information displayed on the labels and reports will be defined by the standards or recommended practices to which they have been tested to. These labels should display some combination of the following information but will differ depending on the standard and manufacturer:

- Name of manufacturer

- Filter model or part number or identification

- Filter serial number

- Standard tested to or followed

- Grade or type of filter as defined by the standard

- Tested airflow rate

- Overall performance in penetration to efficiency

- Pressure drop of filter at tested airflow rate

- Leak test results

- Arrow indicating direction of airflow during tests

When selecting a filter, ensure it bears a test marking in compliance with IEST or EN 1822 and be sure to select the right type or class and grade of filter for your application. Remember that minimum filter efficiency is the minimum efficiency for the MPPS listed and that your filter efficiency increases with both larger and smaller particle sizes.