Design Considerations for Natatorium Ventilation

Designing a ventilation system for a swimming pool can be tricky. For occupant comfort, these facilities require 40 to 60% relative humidity to be maintained year round. For swimmers, a humidity range of 50 to 60% is most comfortable. However, humidity levels below 50% can significantly increase energy consumption, while humidity levels above 60% can cause damage due to mold, mildew and condensation.

In addition to the humidity requirements, swimming pools typically require higher air temperatures. The ventilation system must supply air temperatures ranging from 75°F to 90°F (24°C to 32°C), depending on the type of pool area, while also providing sufficient outside air for the pool area.

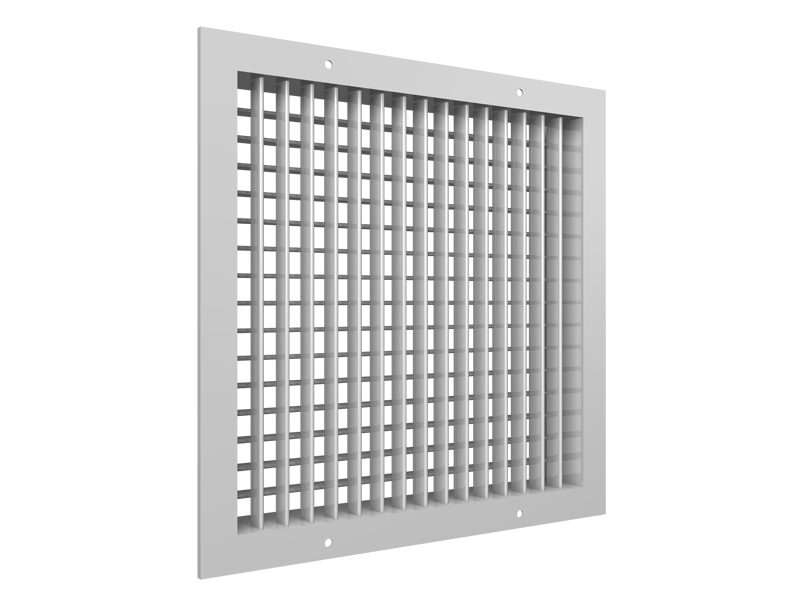

The 600 Series aluminum grille is an excellent option for ventilation considerations in pools or natatoriums.

Swimming pools are routinely treated with chemicals to maintain good water quality, filtration, pH levels and water heating. Failure to maintain proper chemistry in the pool water causes serious air quality problems and deterioration of mechanical and building systems. Air quality issues are usually caused by the creation of combined chlorine which results from the reaction of chlorine and biological waste.

ASHRAE Standard 62 prescribes outdoor air ventilation rates which are intended to provide acceptable air quality conditions for the average pool using chlorine for its primary disinfection process, which applies to the average pool. This ventilation requirement may be excessive for private pools and installations with low use, and may prove inadequate for high occupancy public installations. For further information about determining ventilation requirements for swimming pools, please refer to the ASHRAE Applications Handbook.

When laying out the ventilation system, the balance between ventilation air and exhaust air must be controlled to maintain a negative pressure in the pool room space in order to prevent moisture and odors from migrating to other parts of the building. Supply air must be delivered into the breathing zone at the pool deck to provide adequate air quality. Low level supply outlets are ideal, but in many cases the air is supplied from ducts at high level. In this case the diffuser throw must be carefully selected to project into the breathing zone without causing drafts. Care should also be taken to ensure that the space receives proper air changes and homogeneous air quality throughout the entire space. Supply air should be directed against interior envelope surfaces which also are prone to condensation, particularly windows.

Some air movement at the deck and pool water level is essential to ensure acceptable air quality by moving contaminated air towards an exhaust point and to control combined chlorine released at the water surface. However, excessive air velocity over the water will cause unwanted evaporation.

A designer cannot use the same air velocity standards in a pool area as they would for other areas. In a pool, the occupants are typically wearing less clothing and may be wet, therefore prone to a sensation of draft even at low room air velocity. Air velocities in the occupied zone of a pool should generally be kept less than thirty feet per minute. This requires special care in air outlet selection, particularly with throw.

Return and exhaust air inlets need to be located in order to recover the warm humid air and return it to the ventilation system for treatment and to minimize recirculation of combined chlorine. Return grilles should be located both low and high in the space to recover the warm humid air and to minimize the recirculation of combined chlorine. Exhaust air inlets are best located directly above whirlpools, which are the warmest areas. The exhaust air is taken directly outside the building.

The aluminum LBP linear bar grille another optimum choice for swimming pool environments.

When selecting grilles, registers and diffusers for swimming pool applications, it is critical that they be resistant to rusting and corrosion. Stainless steel is not recommended in pool areas since it is readily attacked by chlorides in the moist environment and corrodes. Aluminum construction is the optimum choice for swimming pool environments.

Some popular choices are:

- LBP linear bar grilles

- 600 Series supply and return grilles

- 97 and 98 Series gym grilles

- Custom Flow AdjustaSlot architectural slot diffusers

- AHCD drum louvers

To learn more about grilles, registers and diffusers (GRD), download the GRD Product Guide, or contact one of our application engineers at grd@priceindustries.com for product support.