Reducing overall energy consumption with Chilled Beams

In modern buildings, the heating, cooling, and ventilation systems consume a large portion of the total energy use. This creates an obvious target when looking for areas where improvements and optimizations can reduce annual energy consumption. Costs associated with these improvements can be reduced year over year. Within the HVAC system, the largest consumer of energy will typically be fan energy. Using hydronic systems to transport heating or cooling energy throughout a building is a great way to dramatically reduce the overall energy consumption of the entire HVAC system.

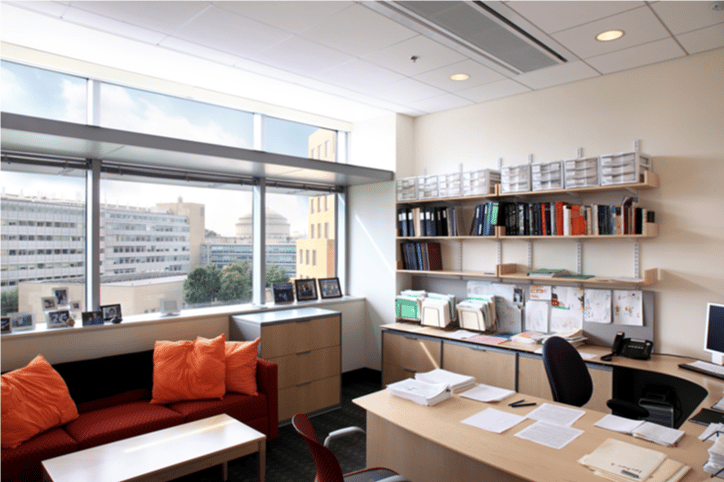

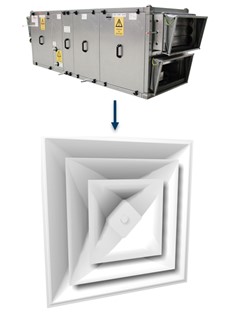

Chilled Beams can help shift the heating and cooling burden off the air handler (Figure 1) by taking advantage of a water coil within the occupied space. Air is induced through the water coil without the use of fans by creating a low pressure zone above the coil.

Figure 1: Typical air handler supplying heating and cooling to HVAC system

Figure 1: Typical air handler supplying heating and cooling to HVAC system

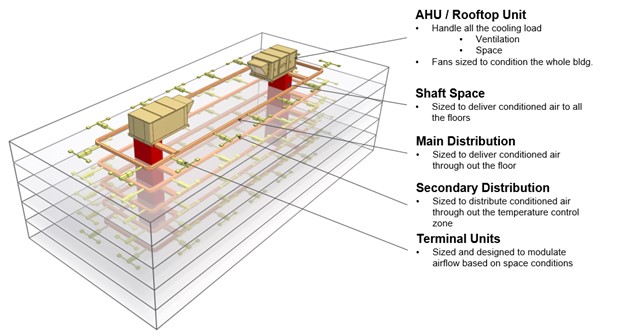

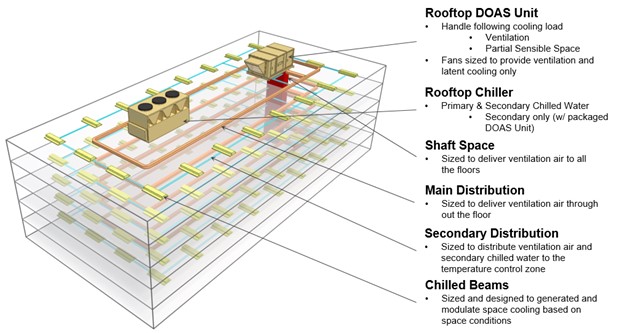

Typically, anywhere from 3 to 6 times the amount of airflow supplied to the Chilled Beam is induced across the water coil, shifting a large portion of the heating and cooling load directly to the boiler or chiller (Figure 2), and reducing the air handler load.

Figure 2: Chilled Beam layout for a similarly sized building. In this case, the chiller needs to increase in capacity, but the air system may be reduced by as much as 50-70%.

Figure 2: Chilled Beam layout for a similarly sized building. In this case, the chiller needs to increase in capacity, but the air system may be reduced by as much as 50-70%.

A highly optimized Chilled Beam design can see as much as 75% of the sensible cooling load treated directly by the chiller, leaving only 25% to be treated by the air handler. Though the building heating and cooling needs do not change when switching from a VAV system to a Chilled Beam system, a large portion of those loads can be treated without the need of additional airflow. This allows the main air handler to be sized for ventilation requirements while still satisfying the heating and cooling needs throughout the building.

Figure 3: A five-story building with a two riser and two air handler layout

Figure 4: A five-story building with a single air handler feeding Chilled Beams

While many of the decisions driving a system design towards Chilled Beams involve energy consumption, there are many other benefits surrounding the reduction in airflow. Lower ductwork costs, decreased floor to floor heights, reduced noise, and ease of maintenance can all be improved when lowering the airflows to the levels required for a Chilled Beam system.

To learn more about Chilled Beams, contact beamteam@priceindustries.com.