In the HVAC design world, there is some uncertainty about the application of new and existing air distribution technologies since codes change so quickly and sometimes drastically. Customer mock-ups of the proposed HVAC design for a specific space are a great way to help resolve design uncertainty.

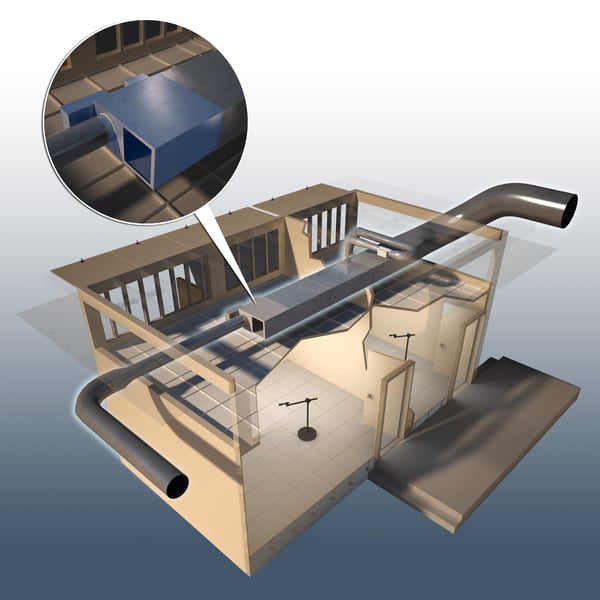

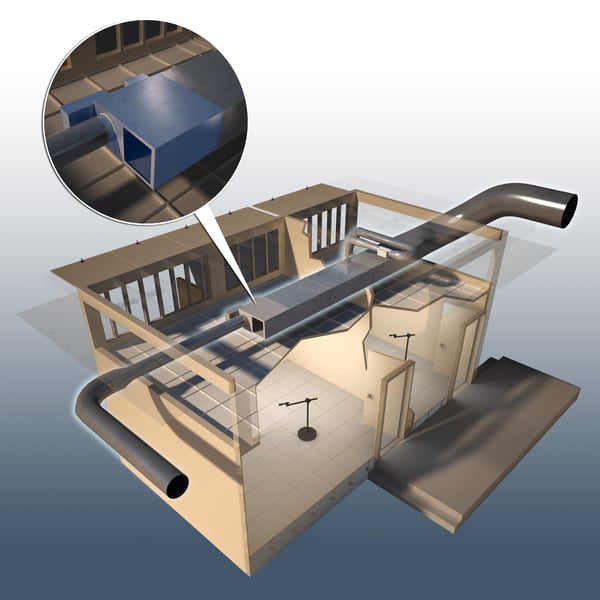

Atlanta’s In-Situ Acoustical Test Chamber

Bringing customers to our facilities only helps them understand the wide range of solutions we offer.

A mock-up would ideally include the representative, design engineer, architect, and owner. This diversity makes for a lasting impression and is more likely to lead to the design being based upon Price rather than a competitor. This impression can last a long time -- some designers and contractors recall mock-ups from over ten years ago!

Our mock-ups are typically categorized as:

- Acoustical

- Energy

- Physical performance.

ACOUSTICAL

There are two types of acoustical mock-ups available:

IN-SITU

An in-situ test is a measurement of the radiated and discharge sound characteristics of a specific device. A common in-situ test involves installing a terminal unit in a ceiling cavity above a room that has an acoustical ceiling with no penetrations allows for direct measurement of radiated sound in a space that approximates the size and construction of a typical private office. The terminal unit has both primary and discharge air duct connections. Discharge air is passed through a divider section in the plenum, allowing little or no radiated sound from the terminal to penetrate into the plenum over the discharge sound room. Then a specific amount of discharge air is directed through a diffuser in the ceiling of the discharge sound room, which allows direct measurement of discharge sound.

With so many other installation types available, we are capable of building a variety of spaces and product configurations. The following examples briefly describe some of the in-situ options we are capable of offering:

- A replica patient room built with acoustical tiles, drywall finish, and chilled beams installed in the ceiling. A microphone in the patient room is used to measure the beam's sound level in the environment.

- An exposed fan powered unit in a replica museum/art gallery to measure radiated sound of the exposed terminal.

- General office space built with testing of products installed in various locations to determine the optimal layout.

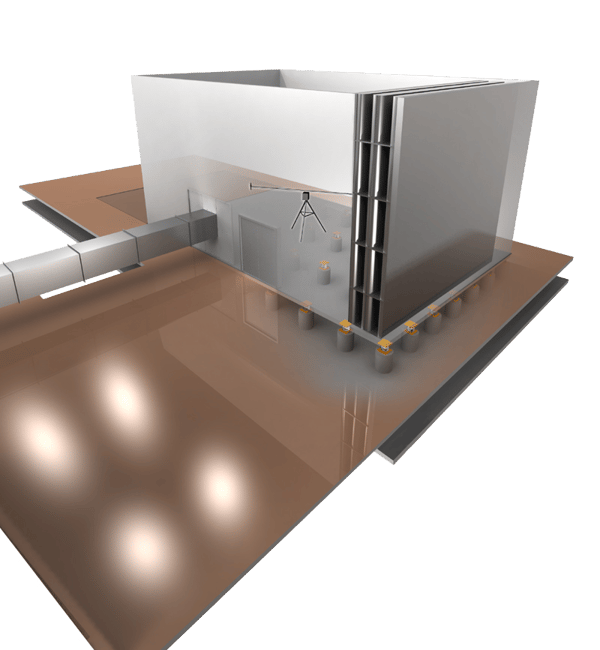

REVERBERANT

A reverberant test is a measurement of the sound characteristics taken per a specific test standard such as

ASHRAE Standard 70 or ASHRAE Standard 130. The results are a quantification of the sound power generated by the device in question.

Winnipeg’s Reverberant Room

ENERGY

One type of test for energy characteristics is a

chilled beam test in the Hydronic Test Chamber located in

Price Research Center North (PRCN), which highlights the unique testing capabilities of PRCN. There is only one other similar test chamber in North America—you would have to travel to Europe to find a chamber of equivalent accuracy. Other types of energy tests include

fan coil performance and fan energy consumption.

Hydronic Test Chamber in Winnipeg

PHYSICAL PERFORMANCE

Physical tests include throw distance for a diffuser, pressure drop across a terminal unit primary valve, or temperature mixing characteristics of a dual duct terminal. These mock-ups can take place at either the Atlanta or Winnipeg location, depending on the measurements needed.

Our mock-up capabilities are perfect for unusual applications of a technology, or when the designer, owner or architect is uncertain how a system will operate. We have several excellent, ready-to-go, full-scale mock-up areas in Atlanta and Winnipeg.

- A large mock-up area that highlights displacement, chilled beams, and overhead air distribution and simulates loading for occupants, as well as shell gain or loss.

One of several mock-up rooms

- A patient room highlighting air distribution methods that meet the requirements of ASHRAE Standard 170.

Patient Room

- A surgical space with operating table and surgical lights, capable of demonstrating two common cleanroom air distribution methods: perimeter curtain and laminar flow.

.jpg?width=600&name=OR_rooms_Sept62013%20(17).jpg)

Operating room air distribution demo room

Smoke demonstration of a displacement system with heat source

Please consider utilizing our mock-up services. You will be pleased with how well received they are by your clients.

For more information, please see the Price Engineer’s HVAC Handbook or email info@priceindustries.com with specific mock-up questions.

.jpg?width=600&name=OR_rooms_Sept62013%20(17).jpg)